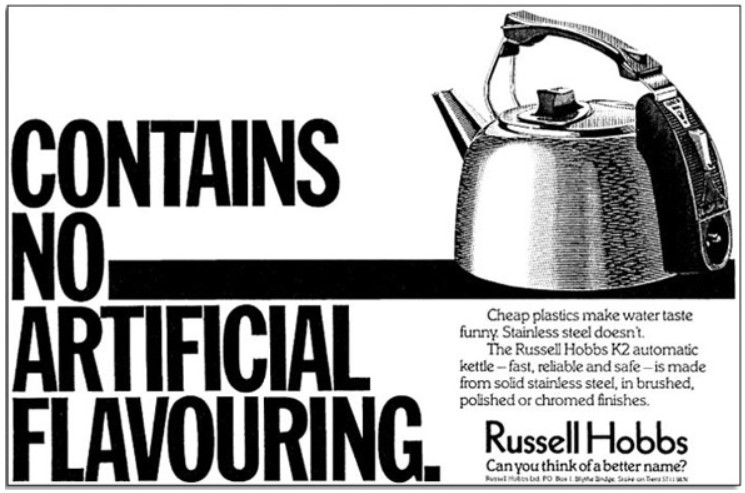

Think back 30 years, and if you can’t, ask anyone over the age of 42. In the place you grew up, how old was the kettle? It might seem a strange question, but as a (slightly odd) child, I noticed stuff like that. I can fondly remember my parents’ own Russell Hobbs K2 kettle, which had been given to them as a wedding gift and was still going strong after they divorced, 25 years later. Unlike their marriage, the kettle was well engineered, robust and easy to mend.

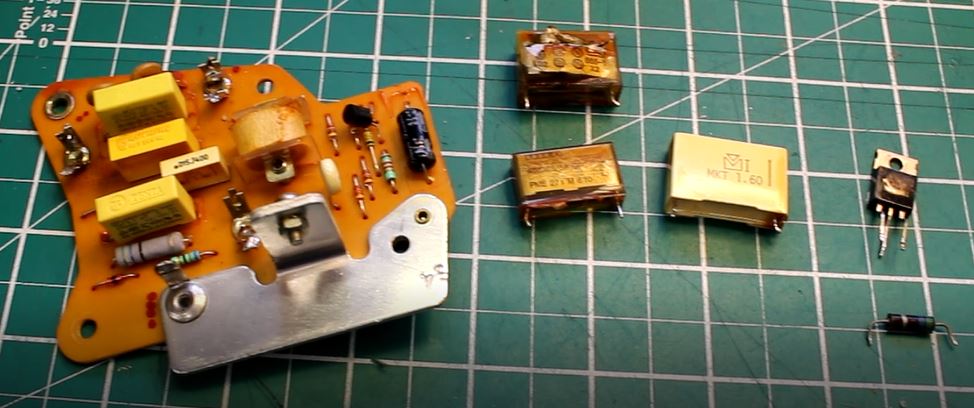

Not long ago, long service was expected from appliances and my friends and relatives had similar experiences. Trust me, I’ve asked them. Buying spare parts was also a thing. You could easily repair kettles of that vintage with basic tools and without the need of a yet-to-be-invented online video. Hardware shops would stock cost-effective spare parts like elements and rubber seals to keep your kettle running for longer, but over time, this type of thing has become the reserve of nerds like myself.

During the last 40 years, the market for small appliances such as vacuum cleaners, toasters, kettles and much more has become congested with laughably cheap goods, and while the prices can make items accessible, it’s usually a case of ‘buy cheap, buy twice’.

Manufacturers have perfected built-in obsolescence to such a degree that they can time your product to fail, just after the warranty expires. Bad for many reasons, but the main thing is that a £15 toaster thrown out after two years will probably end up as landfill. There are free, environmentally kinder disposal routes available from your local council in the UK, but many people just don’t bother. Sad, but true.

It’s still possible to buy something well-designed and robust that will be supported by a responsible manufacturer, you just need to know what to look for.

Do you really need it?

Just because your friend has a kettle with an interactive disco display controlled by their iPhone, do you need one? Probably not. No one does. Google ‘the best kettle’ and you’ll find products that have more knobs and whistles than a power station. This makes them more complicated and likely to go wrong in the future and contain more precious metals, increasing their environmental impact. Remember what you need the product to do. Keep it simple.

How long will it last, will it be any good?

This is a tricky one to quantify as lots of things affect that. But ask yourself, is a kettle costing a tenner going to be a family heirloom to hand-down? Probably not. It will boil water, it will make a lot of noise, it will be inefficient. Take customer reviews on Amazon with a pinch of salt. Trust organisations such as ‘Which’ to guide you on matters of performance and longevity before handing over your hard-earned wedge.

Can I get help when I need it?

Many retailers and manufacturers are not set up to take care of your product once it’s in your hands. At the end of your twelve-month warranty, is there a local agent or are there spares available to fix your product, when you need it? Before making a purchase, do some online research on your chosen toaster manufacturer. Do they have a help desk, can they supply reasonably priced parts, are there engineers out there who can help repair your item? Responsible manufacturers are out there…

Russell Hobbs K65, Henry HVR160 vacuum cleaner, Kenwood Kmix KMX750 Dualit classic toaster. What do they all have in common? All have reasonable support from the manufacturer, after purchase.

Give yourself time to work this stuff out, and you’ll end up replacing your appliance less often. Better still, you’ll be able to fix it when it goes wrong, saving it from becoming waste. You’ll also be able to pass it on when the time comes, which is a far better thing to do. If buying new isn’t an option, don’t be afraid to buy quality appliances second-hand from places like eBay, Facebook and Gumtree. It might not come in a new box with a receipt, but it’ll still be decent, without costing the earth.

Matt or Fixitworkshop is not affiliated with any of the products shown in this article. The items displayed are for illustration only, but were chosen with care based on Matt’s own repair knowledge and experiences.