One lives and learns and if there’s one thing I definitely know now, it’s that the good people of Worthing (at least) really do love their bread makers!

Back in August, in the spirt of light-hearted environmental consumer advice, I offered my thoughts on what I deemed to be ‘pointless products’ and crumbs, did I rattle a few bread bins! Almost 4 amiable souls took the time to share their thoughts on the subject too, extolling the virtues of their trusted kitchen friends. Some even shared a few photos of their finest loaf creations; the most exquisite that I have ever seen, it must be said. At yeast, most of you saw the funny side I think, but others thought that I was being a little childish. So this article will be a little more proven, I hope.

To those who rose-up, a little browned-off by my distaste for these machines, I say this; it was only a bit of half-baked fun. You’ve really got to roll with it!

Turning to more serious matters. When it comes to our current environmental issues it seems more than ever that some campaigns, propaganda, even official advice, must be taken with a pinch of salt. Of course, I too am a consumer of online adverts, original articles and general broadcast media and I find myself increasingly starting to doubt that one can have one’s cake and eat it. Right, enough of the baking buns, sorry, puns.

Despite the typical British Summer we’ve been enjoying here in the UK, it’s been Armageddon on the continent. And, if you’ve been watching any mainstream news these last few months, you would have seen European reports showing newly designed weather maps with splashes of ferocious oranges, blood-reds and deathly maroons, possibly designed by The Terminator, telling us the World is boiling.

Is it all part of a ‘big plan’ to discourage would-be travellers from taking polluting flights to far-away, warmer climes? Are all the ‘wild’ fires, naturally occurring? Whatever your views on climate change, it would seem that broadcast messaging is nudging us to stay home, stay indoors and don’t move. Remind you of anything?

Anyway, assuming you’re still with me (thanks by the way), I certainly don’t claim to have expert knowledge on environmental change, CO2 emissions, the latest breakthroughs or Government policy. However, I do have a sprinkling of knowledge on most of these things, enough to say that we have a global population of over 8 billion humans (and rising), many living in or gaining ‘Western lifestyles’ (food production, transport, devices to state a few), so it doesn’t take the mind of Einstein to realise that we’ve had an effect on our environment since we began farming, and that effect is probably speeding up in a way that evolution hasn’t seen before. So, before you rush out to buy the latest energy saving, connected device made far, far away, I urge you to consider something else too.

In The West, we import thousands of tons of electrical items, well anything with a plug on it, from The Far East. Phones, tablets, toasters, kettles, pop-corn makers (to name a handful) are all made thousands of miles away, and are sold at affordable prices for us to enjoy, the very next day if you like! Also, you can’t seemingly buy any of these things without it being Internet connected, not even a bread maker! This is good news for retailers, but are items made at a price (not quality), in far-away, out-of-sight factories, shipped all around the world, really a good thing for us? Is the latest ‘online ready’, eco-device, always better for the environment? Is it ever a smarter, greener choice to ditch what you have, in order to do the ‘right thing’ by our planet.

Combine the complicated product route to market ‘journey’ with a short life expectancy (or very planned obsolescence), with a lack of in-country repair support, and the whole thing starts to sound like an environmental disaster. Doesn’t it? Some say that the average smartphone’s life is comparable to a pair of jeans, scary when you think about it. And what about the giant computing power; Petabytes of storage, precious metals, the air conditioning, and land that the data warehouses around the world use to make all the connectivity possible? It’s all starting to sound a bit bleak, really.

Years ago, when I was a young BT apprentice, Dave, (a wise colleague and friend of mine) once said that the trouble with the world now is that it’s ‘gone global’. We all laughed at the time, but now I’m older (and maybe a little wiser), I actually see what he meant.

Our thirst for the latest and best has generated a throw-away culture for sure, and if we carry on, deep down, we all know where it’s headed. But the tech stable door is well and truly open, and you, nor I, would favour heading back to 12th Century lifestyles. No one I know would want to turn off YouTube, Instagram, TikTok and Twitter (to name a few).

Social media is a great way to keep in touch, but don’t forget how the platforms pay the bills. As a brand, or if you have the cash, social media gives virtually instant connectivity to the minds of folk most likely to part with their hard-earned money. It’s a powerful conduit to nudge minds, to influence behaviours and to extract pound from your pocket. Judge me as you will, but I suspect that many people, with a specially targeted, guilt-inducing, tear-jerking, warm-hug, ‘we’ll make it all better again for you’, advert could be made to ‘do the right thing’ and buy just about anything today! Dial-in some world-poverty, environmental damage, and little war, and buyers are putty in the brand’s hands. As with all sales pitches, there’s always a catch… don’t believe the hype!

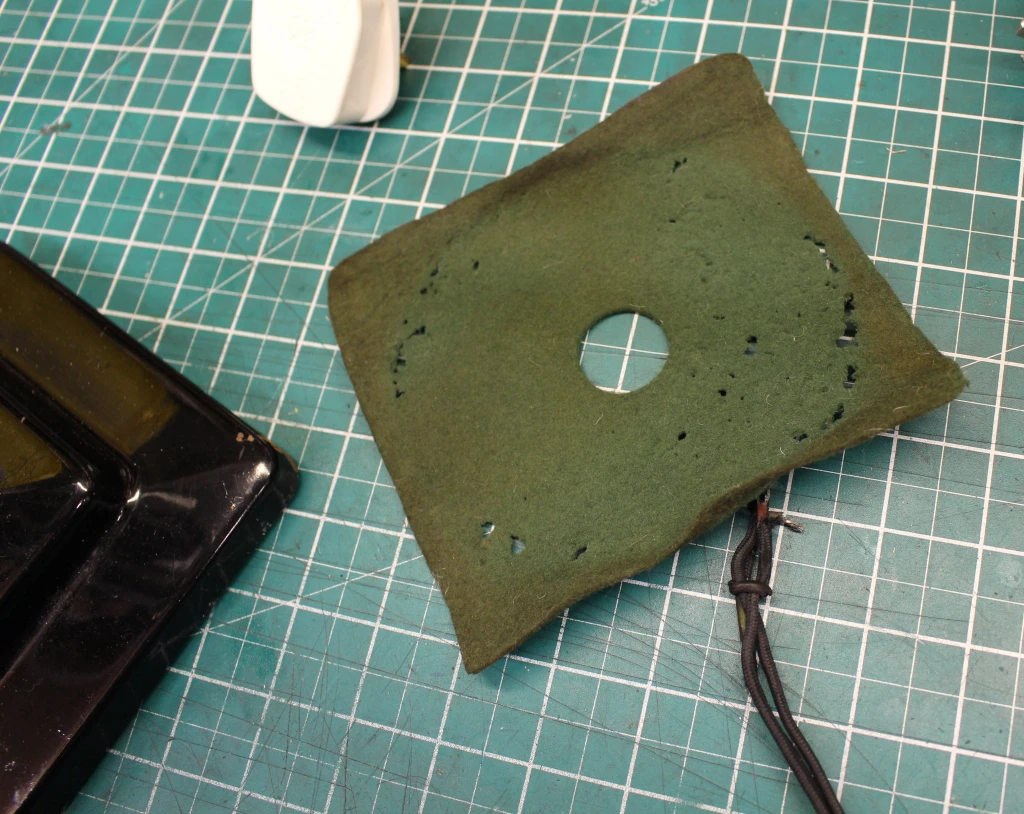

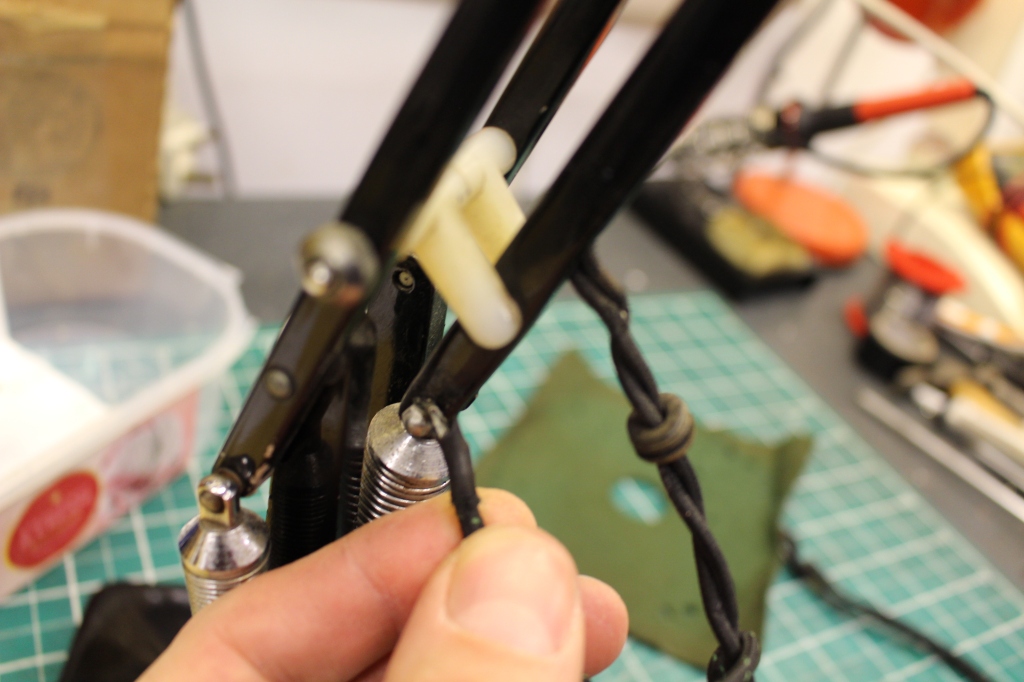

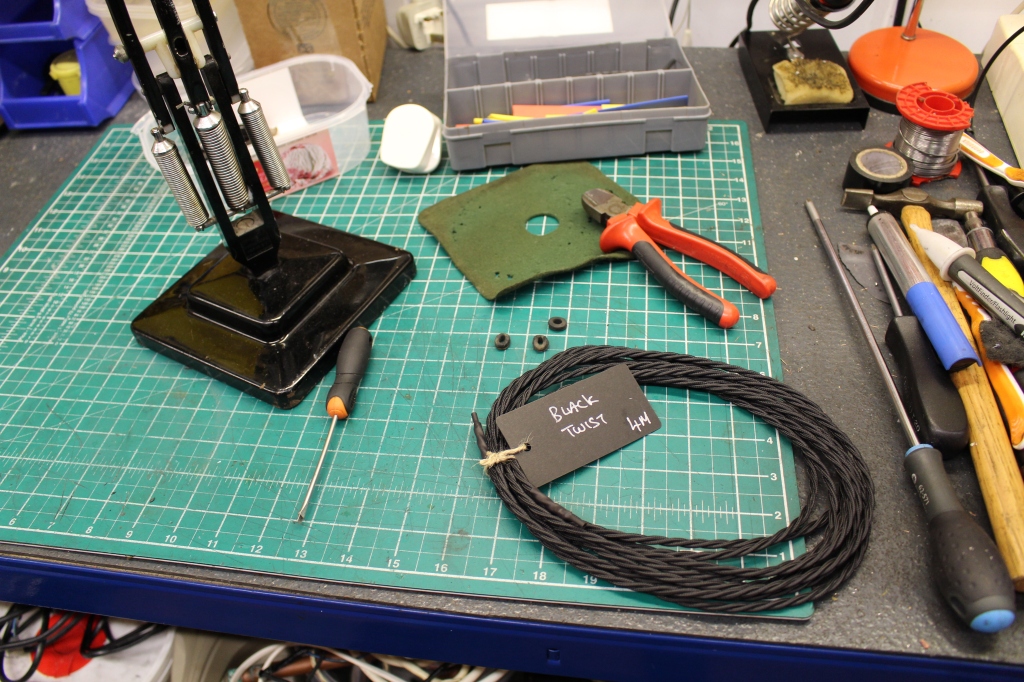

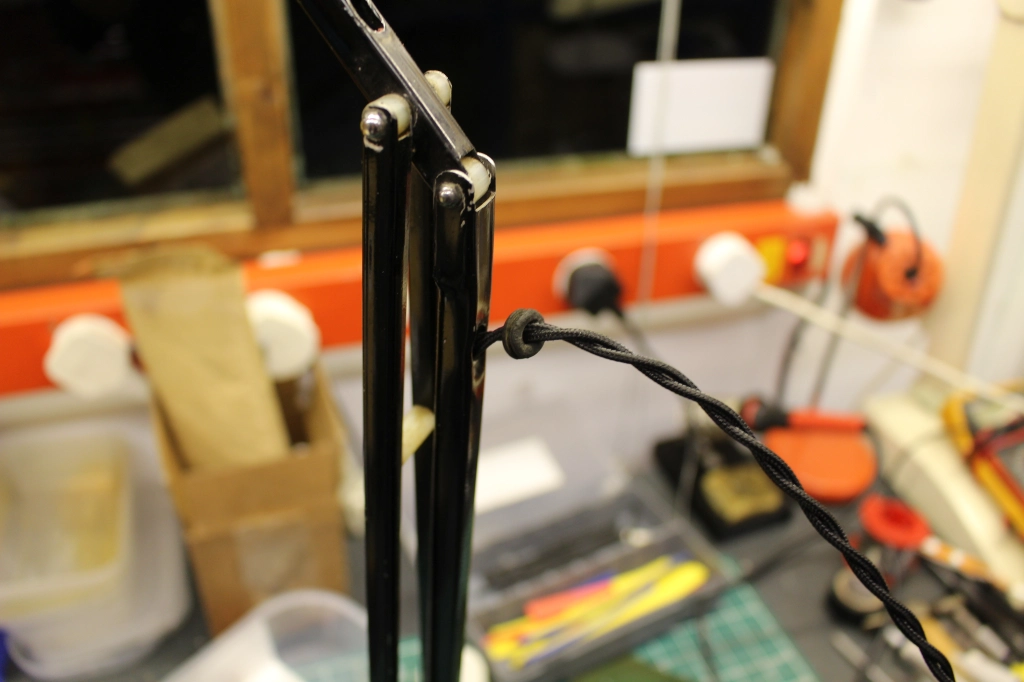

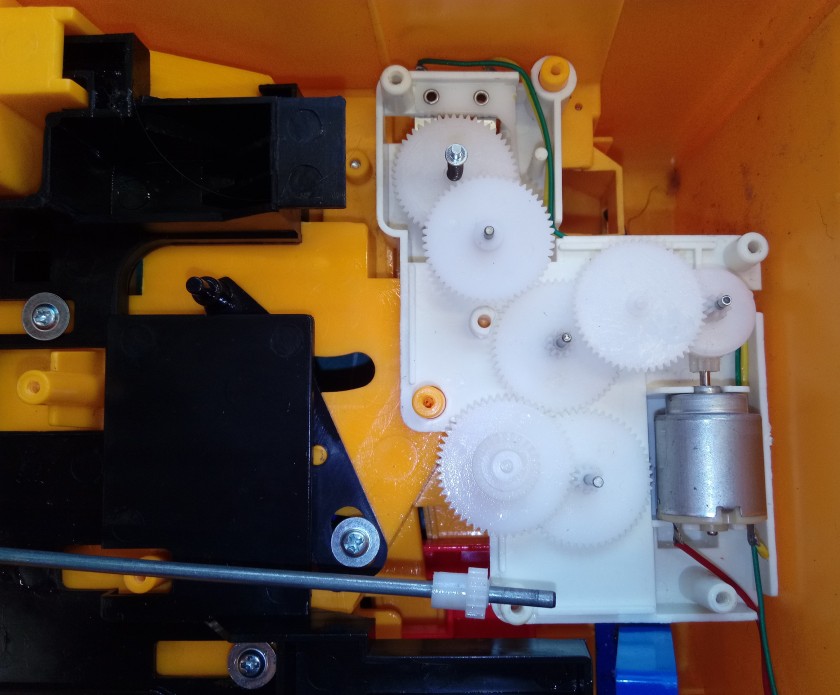

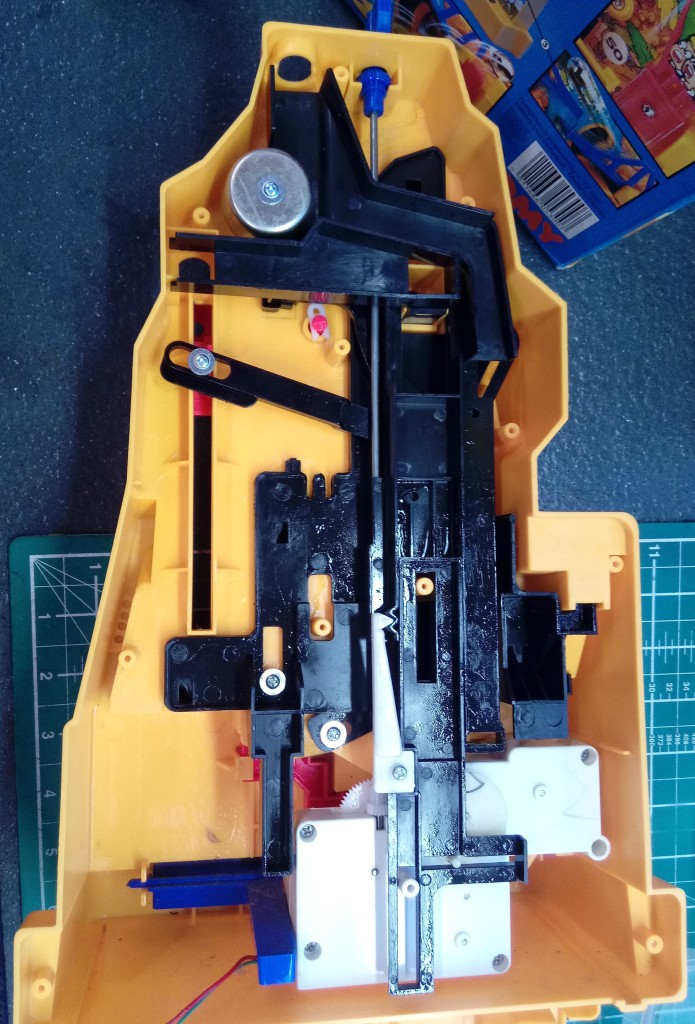

Back in workshop-land this month, it’s been a right-old assorted bag of customer requests! I’ve had quite the mix of items in for repair. Lamps, toys, vacuum cleaners and a CD/ radio to name a few, but despite the variation, there are common themes that link all these items together, in a good way.

Spares were easily available, the item’s design allowed for disassembly and reassembly and I could see individual components with my own eyes! The technology was not out-of-date, it didn’t need an upgrade and it was all still as relevant today as it was at the time of purchase.

A good talking point with friends for sure, but a ‘connected toaster’ that links to your smartphone is probably not a good idea. The Internet bit inside will no doubt fail before the rest of the appliance, and how many WiFi devices do you think will exist in even 5 years? It’s therefore likely that something like this probably won’t last longer than a smartphone. And in my experience, these things are rarely supported by the manufacturer in terms of spare parts. If they have any kind of post-guarantee support, it’s usually not economically viable to bring the item back from the brink.

How to wrap this up then? More than ever, it seems, we all lead busy lives and the vast majority of us are connected to various platforms via our phones, at some time. Indeed recently, on our family holiday this summer, I saw many people from all countries, busy on their phones, by the pool, at mealtimes and even in the sea, throughout the day. Now, I’m not saying that I don’t check my phone, but social media can be like a sugar-rush, addictive for many, and advertisers know this. This means that now, more than ever, it’s possible to link your likes, news, political interests, friends’ network and viewing habits to new products likely to match your spending profile.

If you’ve watched environmental content on YouTube, or have bought solar energy for example, Google knows that you’re likely to be concerned about climate change. Many of us are.

I’m an aspiring optimist, and as a big believer in new technology and global, visionary projects, if delivered by our best engineers, I think we can at least help curb the negative effect we’re all having on the planet.

Eco-inspired, connected-products can make us feel like we’re doing our bit, but clickbait purchases of short-sighted lithium powered gadgets and cars, with limited or no support, can only be bad news.

If it works, and is useful, don’t chuck it out. Maintain your stuff and enjoy all the life an item has to give.

The most environmentally sustainable and cheapest products out there, are probably the things you already have.

Matt.

PS, don’t forget to check out Retro Electro Workshop on UKTV Play.