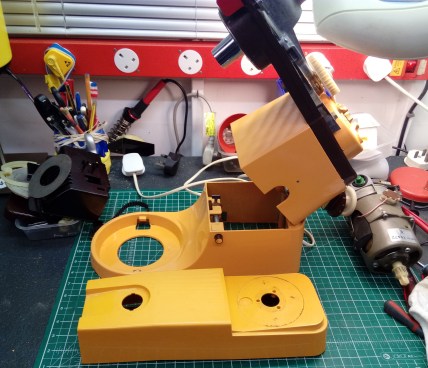

Why oh why oh why are more kitchen machines not orange? I mean, just look at this beauty. Rare-ish and as a Chef spotter, I think the only time I’ve seen another is on the kids’ TV program, Waffle the Wonder Dog on Cbeebies, here in the UK. Do you have one in another funky colour? If so, please send me a picture!

An orange Chef in the workshop: It was like Christmas had come early.

Make and model: Kenwood Chef A901 (orange)

Fault reported: No go

Cost of replacement: About £300

Cost of parts: £13.74

Hours spent on repair: 2

Tools needed: Cutters, screwdriver, soldering iron, multi-meter, cleaning tools

Sundry items: Light oil

Repair difficulty: 5/10

Cups of tea: 1

Cheesecakes: 2

The Chef had actually been working for a living since it provided daily assistance in the production of artisan cheesecakes, being sold at a local market. Recently it had decided to start a smoking habit and then go on strike leaving the owner in a bit of a muddle and customers with rumbling tummies. That simply wouldn’t do.

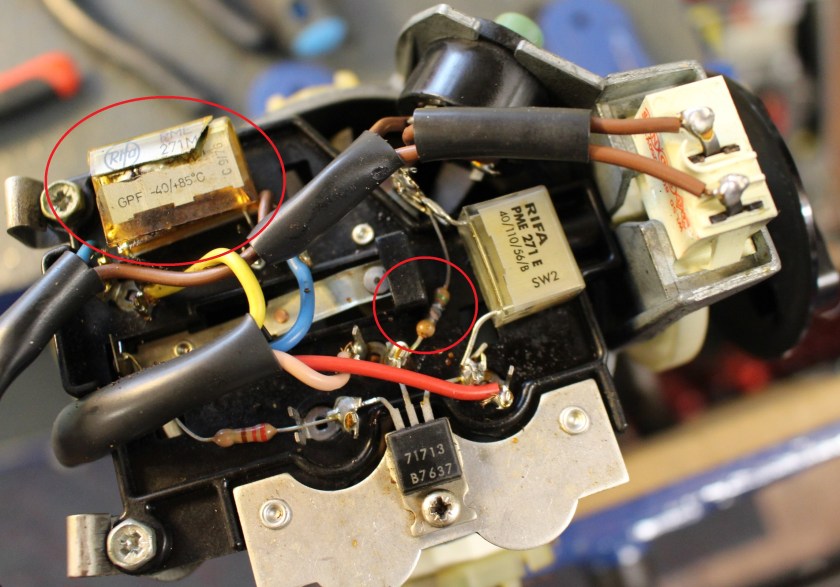

Anyway, on with the repair. Opening up the casing revealed the problem straightaway. One of the capacitors had failed and a resistor had burned out, leaving a failed circuit.

With a decent repair kit bought (from eBay), I replaced all components relating to the speed control circuit, which made the motor run again. I also replaced all the machine’s 5 feet, since the originals had long since gone to mush, something they all do with age. Since the motor was out of the unit, I took the trouble to adjust the motor’s end float and oil the bearings, for ultra-smooth running. Very satisfying.

With the casing all back together, I gave the machine a light T-Cut and polish to make it look as good as new and despite its 30-odd years and the odd bit of flaky paint, I think you’ll agree- it looks fab.

PS, thanks to Andrew for supplying the very yummy scrummy, lime cheescakes.