In readiness for a winter of discontent, I’ve already removed the thermostat’s wiring and have prepared thick jumpers for the whole family, made with the added warmth that only loft insulation can bring. I impressed myself with this stroke of genius and wonder why no-one else has ever tried this before? Can’t imagine why.

There’s a lot of talk about ways to save money on social media at the moment. One only has to do a bit of Googling to learn what we should stop doing or unplug next to save money. There’s an old saying though that usually stands true: Don’t sweat the small stuff.

Anyway, where was I? Back in the summer, I had an-over-the-wall conversation with my neighbour, Liz. It started off in the usual light-hearted manner, talking about this and that, when I heard a whistle coming from Liz’s kitchen, a noise which took me back to sometime in the dim and distant past.

Liz had switched to boiling water using a gas stove kettle and reliably informed me that it was ‘cheaper and greener’ to brew-up this way, rather than use her trusty modern kettle. I very nearly lost my balance, leaning against our diving wall as I laughed and said, “that’s a load of old cobblers” – did I use cobblers, well something like that anyway. With a slight frown of veiled raged from Liz, we both went off to carry on our evenings, but there was a piece of me worried that I’d offended dear Liz somehow. What to do? I’d almost forgotten about the whole thing until it came up again in conversation recently, but this time via another friend of the family. Rather than scoff this time, I decided to investigate in a shed-like manner to work out who was right, me or Liz.

What is the most efficient way to boil water at the moment?

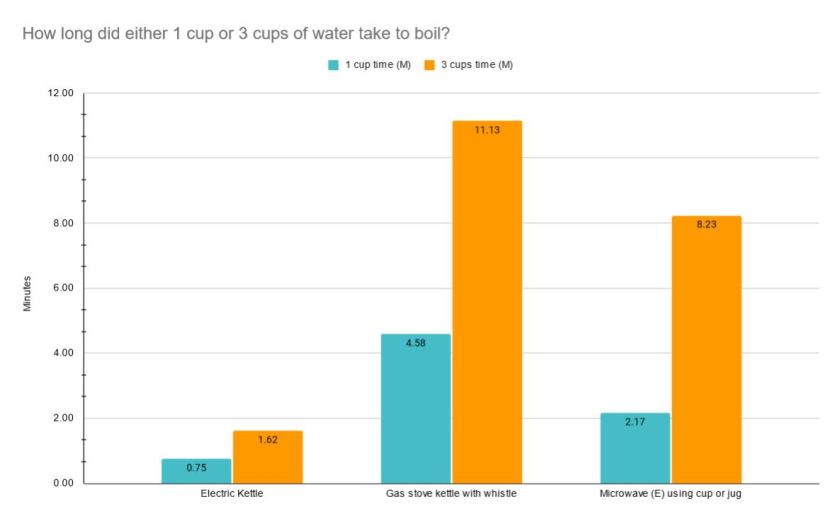

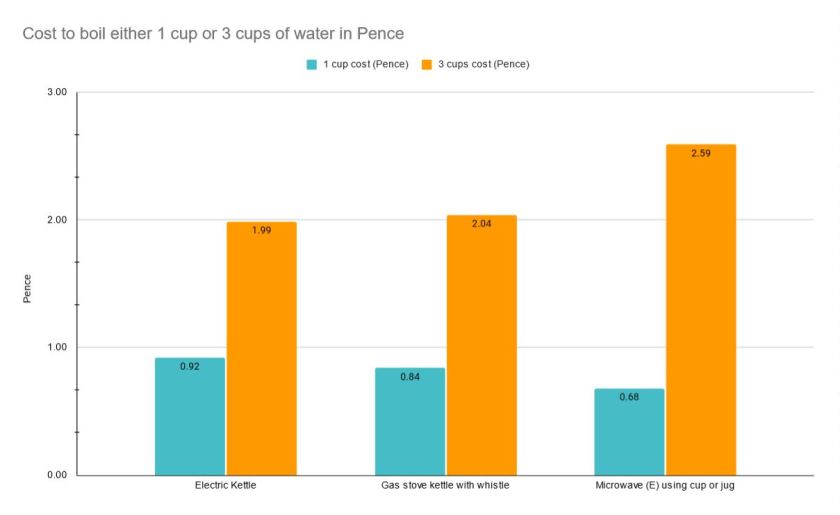

I decided to see just how much one cup (see photo) or three cups of water would take to boil using a modern 2500W electric kettle, a gas stove kettle (hob rated at 1500W) and a jug in an E rated 800W microwave. Just for kicks. Hasn’t everyone done this? I used the same cup for the whole experiment. Water was taken from the cold tap at room temperature. I used the stopwatch on my phone and used a base rate of 29.48p/Kwh for electricity and 7.32p/kWh for gas. We’re with Eon and these rates seem to be ubiquitous at the moment. I timed how long either one cup or three cups would take to boil using each boiling vessel. I started the test from the ‘on’ switch on the kettle, the gas ignited on the hob or the ‘on’ button on the microwave. The test ended when the kettle switch turned off, the stove kettle first whistled and boiling bubbles were observed in the microwave. By now, I’m sure you’re on the edge of your seats.

Everyone’s an expert these days and while I’ve done my best to make this a real-world test using a moderately scientific approach, I’m sure someone out there will drive a coach and horses through my method, but don’t bother, the results are astounding.

THE RESULTS ARE IN

Time matters

If you’re always in a rush and need your cuppa in a flash, then the only way to go is to use a modern electric disc-element kettle, like the one in the photo. Using a microwave was second fastest, but not much faster than the very slow (by comparison) gas stove kettle. One, nil, nil to the electric kettle then.

The real boiling issue – what did it cost?

Gas is cheaper than electricity on my energy tariff, which is a similar story for many other domestic customers at the moment. The microwave proved to be the cheapest method to boil one cup of water followed by gas in this test, but the results changed dramatically when three cups were boiled – a complete reversal in fortunes in fact. Three-way tie.

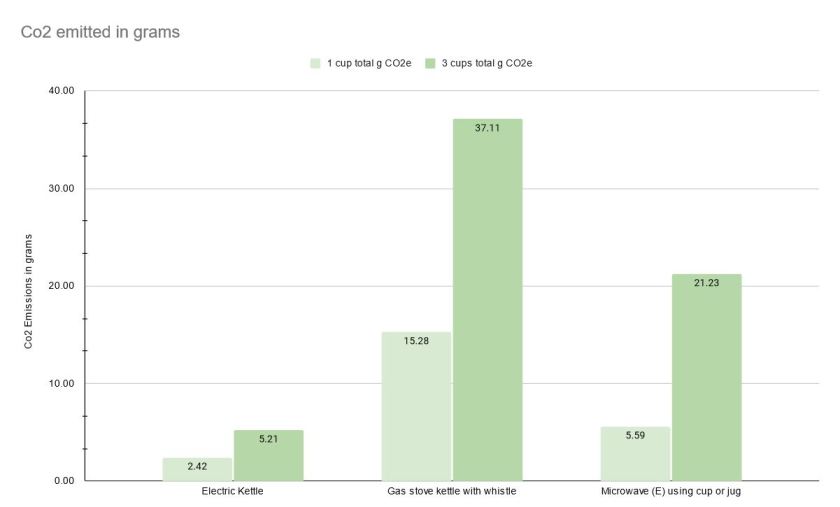

Environmental impact

What about the CO2 emitted? Perhaps the trickiest measure to nail down, but using Defra* approved conversions, based on the kWh for both fuels, it stands to reason that the electric kettle emitted the least CO2 as it was on for the least amount of time. The electric kettle triumphs overall.

*UK Department for Environment, Food & Rural Affairs

So, in conclusion, a gas stove may be cheaper to make a brew for one (at the moment), but one must be careful to measure the water required carefully and a slight increase in the tariff could see all savings easily eroded. The microwave was the wild card entry (my mate Paul’s suggestion) and it proved that it’s a reliable and cheap way of heating, if compared to the stove – for some forms of cooking.

The bottom line is that a modern electric kettle will do the job faster, usually cheaper and cleaner than its rivals. Time for a brew? Go on, treat yourself.