I had an enquiry via this site from a fisherman who was very upset that his trusty Kenwood Chef A901 had given up the ghost. Rather than using the Chef to make Victoria sponges, it had been used to prepare fishing bait. It just demonstrates how versatile these machines are.

Whilst it was in use, the owner witnessed a bang then the smell of burning before the machine came to a halt. The plug was quickly pulled!

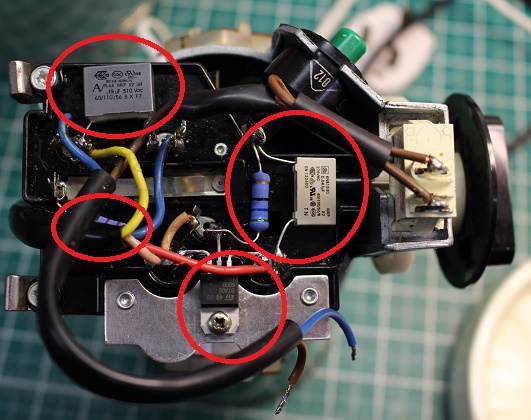

Whilst discussing the fault on the phone, I suspected that the fault was probably due to the failure of the motor speed control circuitry, which is known to fail with age. I had carried out similar repairs to other machines, including my own (in this blog) so agreed to take a look.

I received the machine quickly and upon inspection, the machine had obviously been cared for and considering its age, was in good condition. The smell of burned-out components was clear, lifting it out of the box.

Dismantling the machine and removing the motor on the A901 is fairly straightforward, providing you allow time and make notes on where things go. The components that need to be replaced are very accessible and anyone with moderate soldering skills would be OK with this task.

Luckily, the Chef is very well supported by long-term aftermarket suppliers and I bought an off-the-shelf spares kit at £14.10 delivered, from KAParts (www.kaparts.co.uk) via eBay, featuring upgraded components. This kit is a little dearer, but component technology has moved on since this machine was first on the market, so fitting anything else is a false economy in my opinion.

With the old components removed and replacements fitted, the motor ran smoothly and fully reassembled, the machine is now ready to mix bait mixtures once again. Lovely.

Cost of a new machine: Circa £300 and up. Cost of repair: £44.10 (kit plus my time).

Here’s a little video I made of the repair.

Enjoy.